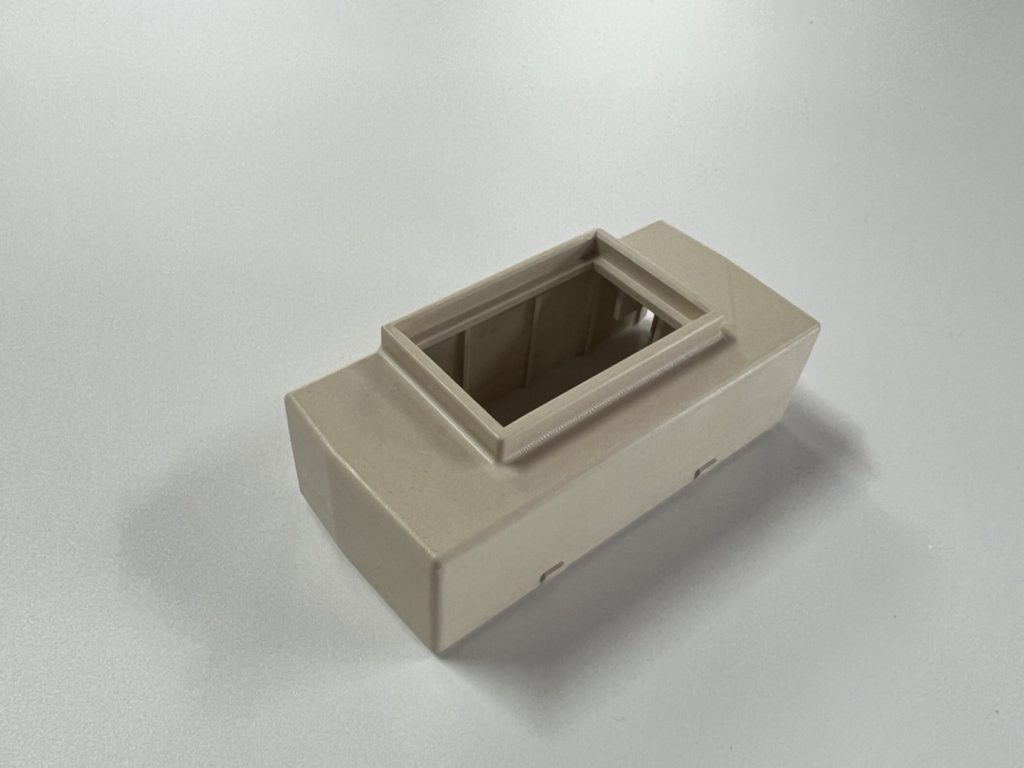

Why You Should Consider Using PEEK Material for CNC Machining at PRE PART?

- PEEK is versatile:

PEEK material is highly versatile and can be machined into different shapes and sizes. Its characteristics make it suitable for numerous applications such as seals, bearings, pumps, and gears in aerospace, automotive, medical, and oil and gas industries. With CNC machining at PRE PART, PEEK can be easily turned, milled, drilled, and tapped, and its surface can be polished to a high finish resulting in an aesthetically pleasing final product. - PEEK offers excellent resistance to chemicals and high temperatures:

PEEK material exhibits excellent resistance to a wide range of chemicals, acids, and bases, making it an ideal material to withstand harsh industrial conditions. This material can maintain its dimensional stability and offers high strain resistance even at high temperatures, making it ideal for use in a variety of precision engineering industries. Compared to metals, PEEK has a lower thermal conductivity, which means it is less prone to thermally induced deformations; an issue that is common in high-temperature applications. - PEEK is lightweight and offers excellent mechanical properties:

PEEK material is lightweight, making it an ideal component material in many sectors where high strength-to-weight ratio is needed. With a modulus of elasticity similar to that of aluminum, its tensile strength is 3-4 times stronger than Acetal and Nylon materials and offers better creep resistance than a lot of other materials in its class. Therefore, PEEK offers excellent mechanical properties for applications that require stress resistance and durability, making it a reliable option for our customers when working with PRE PART. - PEEK is biocompatible and safe for use in medical applications:

Due to its excellent biological and biocompatible properties, PEEK material is safe to use in medical implants that require long-term implantation in the body. It has excellent mechanical properties, and its structure does not interfere with the body’s natural healing process. It also offers a low risk of infection and other complications. PEEK material is popular in Medical CNC machining at PRE PART, for applications, including dental implants, spinal implants, and joint replacements, among others. - PEEK is environmentally friendly:

PEEK is a thermoplastic polymer that is recyclable, meaning the material can be repurposed and used in other applications. PRE PART has a comprehensive approach to sustainability and is committed to developing and promoting environmentally friendly solutions. The use of PEEK in CNC machining is an important step towards reducing waste and promoting sustainable manufacturing practices.

Conclusion:

In conclusion, PEEK material is a versatile, high-performance material that offers numerous benefits, including excellent resistance to chemicals, high temperatures, and high strength-to-weight ratio. Its numerous applications range from aerospace to medical equipment and sustainable manufacturing practices. At PRE PART, we offer advanced CNC machining capabilities that allow us to work with PEEK material for a wide range of applications. We pride ourselves on providing top-of-the-line CNC machining services using the best PEEK material in the market to help our clients achieve their desired outcomes. By choosing PRE PART, you can rest assured that your project will be handled by professionals with a deep understanding of PEEK machining and an unwavering commitment to quality.