Why choose PREPART with CNC milling service?

Are you in the market for a reliable CNC milling service for your business? If so, then chances are that you have been researching the various options available to find a solution that best meets your needs. At PREPART, we understand how daunting it can be when searching for the right CNC machining partner. We strive to make sure our clients receive only the highest quality results and are always up-to-date with new technology and workflows to ensure they get exactly what they need – nothing more, nothing less. In this blog post, I want to give you an insight into why many choose PREPART as their premier supplier of CNC milling services – from accuracy and precision to speed of delivery and cost savings.

Introduce PREPART and CNC milling and its benefits

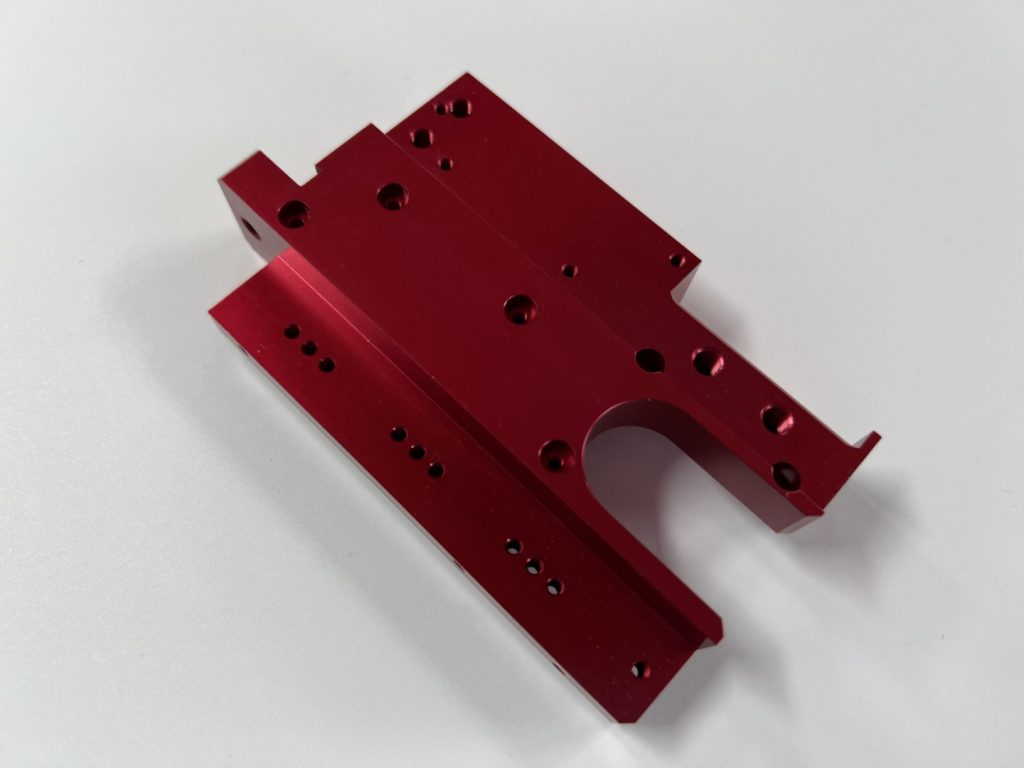

Are you tired of traditional manufacturing methods and looking for something more efficient and precise? Introducing PREPART and CNC milling! PREPART is a leading provider of high-quality CNC machining services, and CNC milling is a process that uses computer-controlled machines to create complex parts and components. The benefits of using PREPART and CNC milling are numerous, including greater accuracy, faster production times, and increased durability of the final product. Additionally, CNC milling allows for greater flexibility in design, as the machines can quickly switch between different cutting patterns and produce parts with intricate details. Embrace the future of manufacturing with PREPART and CNC milling.

Explain why CNC milling is superior to traditional hand-cutting methods

When it comes to precision and efficiency in manufacturing, CNC milling is the way to go. Unlike hand-cutting methods, which are prone to human error and are time-consuming, CNC milling uses computer software to control the cutting tools, resulting in consistent and accurate cuts every time. CNC milling can also work on a variety of materials, from metals to plastics, and can create complex shapes and designs that would be difficult to achieve using traditional methods. Overall, CNC milling not only simplifies the manufacturing process but ultimately produces products of higher quality, making it a superior choice over traditional hand-cutting methods.

Describe the types of material that can be used with CNC milling

CNC milling is a versatile process that allows for a wide variety of materials to be used. Metals such as aluminum, steel, and copper are commonly used in CNC milling due to their durability and strength. Plastics like acrylic, polycarbonate, and ABS are also popular choices because they can be easily machined and offer a range of colors and finishes. Wood is another material that can be used, with hardwoods like oak or maple being ideal for intricate designs. Additionally, composite materials like fiberglass and carbon fiber can withstand extreme temperatures and pressures, making them suitable for aerospace and automotive components. Overall, the range of materials that can be used in CNC milling makes it a flexible and adaptable process for various industries and applications.

Discuss the advantages of using PREPART’s CNC milling service

Using PREPART’s CNC milling service has numerous advantages that make it an ideal choice for various applications. With the utilization of cutting-edge technology, PREPART’s CNC milling service provides consistent, high-quality results with minimal errors. This precision reduces the chances of rework or scrap, saving both time and money. Additionally, the service provides a speedy turnaround time, allowing for the timely delivery of projects. The versatility of the service enables customization of materials, shapes, and sizes, offering greater design flexibility. By trusting PREPART’s CNC milling service, customers can rest assured in the knowledge that their needs are met with accuracy and efficiency.

Detail how customers can benefit from PREPART’s CNC milling services

With PREPART’s CNC milling services, customers can expect a range of benefits that will elevate their production processes. From an increase in precision and accuracy to an improvement in speed and efficiency, the advantages of CNC milling are vast. By leveraging computer-aided design and programming, our CNC machines can create intricate and complex parts with ease, decreasing the likelihood of errors or defects. These services allow for a quicker turnaround time and decreased lead time, meaning customers can get their products to market faster. By utilizing PREPART’s CNC milling services, customers can be confident in the quality and efficiency of their production processes.

Outline the safety measures taken by PREPART when using CNC milling services

When it comes to CNC milling services, safety is a top priority for PREPART. The company places great emphasis on providing a secure working environment for both employees and customers. One of the key safety measures that PREPART takes is to regularly maintain their equipment, ensuring that all machines are in good working condition before every use. Additionally, they engrain safety protocols into their employee training, including safe practices for handling materials, operating machinery, and disposing of waste. They also provide protective gear such as gloves, safety glasses, and earplugs to guarantee the safety of those working in the shop. Overall, PREPART takes all necessary measures to ensure that the safety of its people and the quality of its products are never compromised.

Taking everything into consideration, PREPART is one of the leading companies that understand the importance of cost-effective and reliable CNC milling services for those who choose to go beyond the traditional hand-cutting methods. With its vast array of materials, the CNC milling process offers flexibility and originality to customers who require a specific shape or size. Not only that, but users can feel at ease knowing PREPART implements a range of protocols to ensure their safety while using this cutting-edge technology. Our CNC milling service also utilizes advanced technology to maximize efficiency and produce high-quality results in a shorter amount of time than manual methods. With all these benefits, there’s no better choice when it comes to choosing an efficient and reliable CNC milling provider – PREPART has your back!